Get This Report on Premier Aluminum Llc

Get This Report on Premier Aluminum Llc

Blog Article

6 Simple Techniques For Premier Aluminum Llc

Table of ContentsSome Ideas on Premier Aluminum Llc You Need To KnowNot known Details About Premier Aluminum Llc Premier Aluminum Llc - QuestionsHow Premier Aluminum Llc can Save You Time, Stress, and Money.

(https://issuu.com/premieraluminum)Making use of low expense and unqualified vendors can cause high quality problems, and threw away time and money in the long run. To assist you with the process, below are some things to think about when selecting the best metal spreading distributor.

A company that only utilizes the investment spreading process will certainly try to sell you on why that procedure is best for your application (Aluminum Casting company). What if making use of the sand casting process is best for you and your demands? Rather, try to find a provider that uses a variety of casting processes so the finest choice for YOU is selected

If collaborating with a solitary resource for all of your casting requires is very important to you, the provider requires to be diverse in its capabilities. When integrated with other incorporated abilities, this can help streamline and press the supply base. When selecting the ideal casting provider, cautious consideration ought to be offered to high quality, solution, and price.

6 Simple Techniques For Premier Aluminum Llc

Customers increasingly select casting suppliers who have machining abilities. This can prevent dispute if problems are uncovered throughout machining. If a 3rd party is machining, it may cause "finger-pointing" concerning who is at mistake. Is it a casting issue or a machining concern? If the spreading vendor finds a concern throughout machining, the trouble is solved faster without any disagreement over whose fault it is.

Issue or no, incorporated machining simplifies the supply chain and minimizes managing time and delivery cost prior to the item makes it to the client. What do you require from your casting vendor? Are you seeking somebody to just supply a metal part to your front door or do you need extra? For example, if you do not have internal metallurgy expertise, validate that the distributor can offer assistance in picking the correct alloy based on your particular application - Foundries in Wisconsin.

Others will exceed the letter of the PO to help you save money and time. Do you have requirements for both ferrous and non-ferrous alloys? Some foundries page are limited or specialized. Make certain the vendor can satisfy all your product or alloy requirements to remove the demand for multiple suppliers.

The Best Guide To Premier Aluminum Llc

Research study the supplier's web site. Talk to a sales representative or company associate.

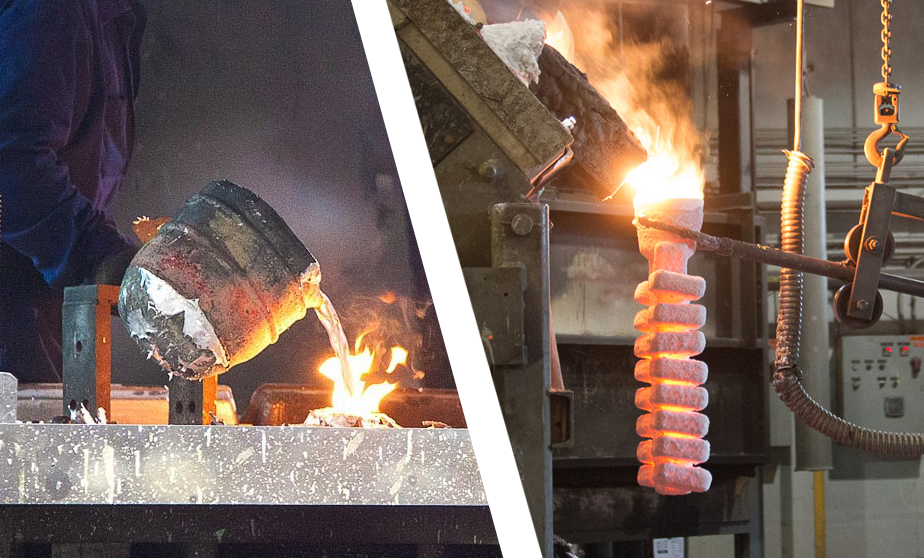

Aluminum is also lightweight and has great corrosion resistance, making it perfect for applications where weight and resilience are important factors. Additionally, aluminum casting is an economical method of production, as it calls for much less power and resources than other approaches. Iron spreading, on the various other hand, involves pouring molten iron right into a mold to create a desired form.

Rumored Buzz on Premier Aluminum Llc

Iron casting is also able to hold up against heats, making it appropriate for usage in applications such as engine parts and industrial machinery. Nevertheless, iron casting can be extra pricey than light weight aluminum spreading as a result of the higher cost of basic materials and the energy needed to melt the iron. When choosing between light weight aluminum spreading and iron casting, it is very important to take into consideration the specific demands of the application.

In verdict, both aluminum spreading and iron casting have their very own distinct benefits and negative aspects. There are 3 sub-processes that fall under the group of die casting: gravity pass away casting (or long-term mold spreading), low-pressure die casting and high-pressure die casting. To get to the completed item, there are three primary alloys utilized as die casting material to choose from: zinc, aluminum and magnesium. Report this page